Game-changing fix for India’s Wastewater Nightmare

Imagine you are standing by the bank of a vibrant river in Gujarat where local fishermen catch fish to feed their families. Today, that river water is dark and mixed with untreated effluents from nearby textile mills. This issue has forced those families to buy bottled water and worry about mysterious skin rashes on their children. This scene is repeated across India, where industrial growth often clashes with environmental health. Our country generates over 72 billion litres of wastewater daily, and 70% of that wastewater is untreated before being released into rivers, soil, and communities. This issue has resulted in poisonous ecosystems and also exacerbates climate woes. As Industries use fossil fuels, they contribute to 24% of India’s carbon dioxide emissions.

To resolve these issues, in 2023 National Green Hydrogen Mission (NGHM) was launched which aims for 5 million metric tonnes (MMT) of green hydrogen production by 2030. It was launched to eliminate fossil fuel imports and power a net-zero future by 2070. After this push, a Bengaluru-based startup Ossus Biorenewables emerged as a beacon of hope. It was founded in 2017 to transform industrial wastewater into green hydrogen fuel and reusable clean water by using their innovative OB HydraCel technology.

Industrial Wastewater Problem in India

India’s industrial boom in sectors like pharmaceuticals, textiles and steel has a dark face: massive wastewater generation loaded with chemical oxygen demanded (COD) pollutants. According to Central Pollution Control Board (CPCB) reports, urban centers alone produce about 72,368 million litres per day (MLD) of sewage and then industrial effluents add another layer – they produce around 13,000-15,000 MLD. At last, treatment capacity lags and over 70% raw sewage gets discharged into rivers like the Sabarmati in Gujarat or the Damodar in Jharkhand which turns them into toxic sludge.

In textile hubs like Surat, workers have to expose themselves to dyes and chemicals daily which leads to their respiratory issues and higher cancer rates for those who rely on nearby contaminated groundwater. This issue costs nearly 1 lakh crore annually in India due to health bills, lower productivity, and environmental cleanup. On the other hand, Industries burn coal for power which results in emissions and waste the organic energy locked in their effluents.

In Jharkhand’s Steel belts, acid-laden runoff killed fish stock and created hardship for tribal communities. Instead of countering these issues, policy gaps make the conditions worse- the fines are too low to deter violators. This cycle can trap millions in poverty and illness without innovative fixes.

Ossus’s Invention: What is the OB HydraCel breakdown

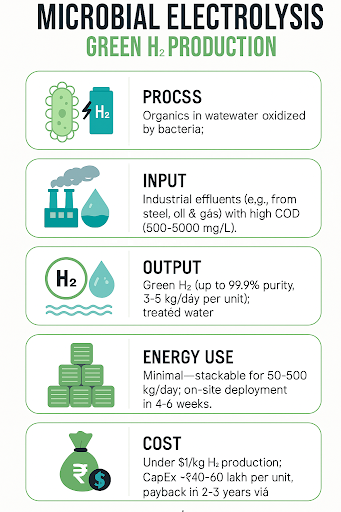

Ossus has used nature’s own cleaning crew- microbes to counter wastewater issues. Their OB HydraCel is an AI-optimised bioreactor that deploys electroactive bacteria to break down organic pollutants through microbial electrolysis. Let me explain more clearly: picture a factory worker in a steel plant with no fear of untreated sludge. Now, the wastewater will flow into a modular unit in which microbes “eat” the organics with the help of a low-voltage electrochemical push. This process splits water molecules and releases high-purity green hydrogen at the cathode while purifying the water for reuse.

This process is elegant and efficient: wastewater will enter, microbes will oxidise carbons at the anode and AI algorithms will provide voltage and flow in real-time for optimal output. Models include “H₂-as-a-service” where Ossus manages operations remotely. It is best for tight industrial spaces, as it’s deployable in containers.

What makes Ossus a game-changing innovation?

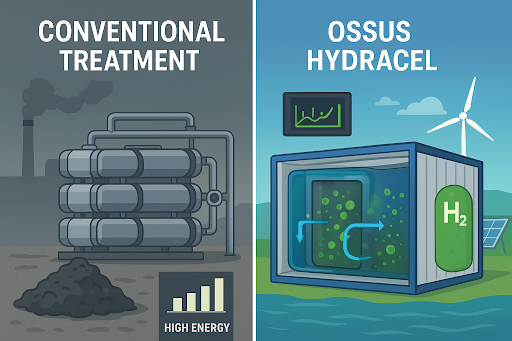

Ossus’s dual ability makes it the game-changer. It can generate green hydrogen while treating water, and all on-site without rare metals or massive grids. Traditional methods treat only 1 problem: reverse osmosis (RO) cleans water but guzzles energy and electrolysis makes H₂. But demands pure water and high power. By using “dirty” wastewater as feedstock, Ossus produces fuel at under $1/Kg – which is half of the cost of grid-based green H₂. In my opinion, it empowers underserved industries where grid access is spotty. Investors love the circular economy vibe: compliance credits plus revenue from H₂ sales. Global microbial fuel cells focus on electricity but Ossus’s AI edge is optimized for India’s variable effluent and it attracts nods from bodies like ONGC.

Implemented Examples in India

A collaboration with Tata Steel’s plant in Jharkhand has produced about 30kg/day of H₂ from steel effluents. It has helped in cutting emissions and reviving birdlife. Workers there share tales of clean discharge ponds.

The ONGC Mehsana pilot in Gujarat, signed in 2024, produces 50 kg/day of H². Additional trials in Telangana’s pharma clusters and Gujarat textiles treat dye-laden water and yield around 10-20 kg/day H₂ per site. Ossus now outputs around 2,000 kg/day across pilots in our nation. It has secured a 2025 award from ONGC for its role in national energy goals.

Existing solutions & Why Ossus stands out

Conventional fixes like anaerobic digestion convert waste into methane but produce sludge and low-value has. RO purifies water expensively and ignores energy potential. Emerging global tech like microbial fuel cells generates power but they scale poorly. Indian peers often focus on biogas and miss H₂’s high-value niche. Ossus overcomes all these issues- no sludge, low energy and AI for 90%+ uptime. A textile owner in Gujarat can become self-reliant and decrease costly imports.

Challenges & Drawbacks

No innovation is flawless. Ossus faces a high initial CapEx which is around 50+ lakh rupees per unit. It’s difficult for small rural industries to adopt. The microbes in the system can become unstable if the wastewater quality changes. Expanding this system to a larger scale needs a stronger infrastructure which is often missing in remote areas. On top of this, slow regulatory approvals and energy losses during electron transfer can create extra hurdles. And hence subsidies and R&D are crucial to drop costs and stabilize tech. It should reach all those factories that are hit by pollution fines.

Future potential

Ossus could supply 10% of India’s H₂ needs by 2030 if it is scaled. It can generate ₹2,500crore revenue and support net-zero pledges. Partnerships with the EU can give us export opportunities that can turn India’s waste problem into a valuable global resource.

Final Reflections: Call to action

In my opinion, industrial wastewater isn’t doom; it’s a hidden gem. Ossus’s innovation unlocks clean energy and reduces water pollution which proves India’s ingenuity while reducing carbon emissions. This innovation requires policy boosts and wider adoption then it could lead to a green & healthier nation.